0538-5089056

0538-5089056

How do you calibrate a bath temperature?

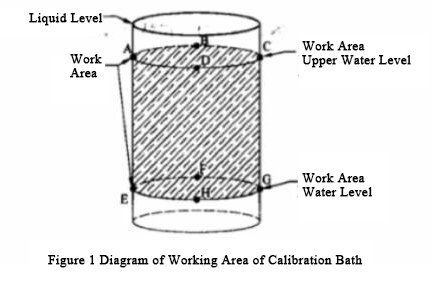

The constant calibrate bath uses liquid as the heat transfer medium, through the temperature control system and the action of stirring or jet device, it reaches the set temperature and keeps the temperature of its internal working area uniform. It is mainly used as constant temperature equipment for verification and calibration of various thermometers or other measuring instruments. Heat pipe grooves can also be tested according to this specification. The schematic diagram of the working area of the constant temperature calibration bath is shown in Figure 1.

Increase the set temperature of the calibrate bath by 10°C, and adjust the heating rate to 1°C/min to heat up the calibration bath. After waiting for 5 minutes, start recording the temperature. Waiting for 5 minutes here is due to two reasons. The first is to control the temperature of the calibrate bath from the steady state to the set 1°C/min heating rate, which generally takes (3~5) min. Secondly, due to the difference in time constant (response time) between different thermal resistances (between different standard platinum resistance thermometers, between standard platinum resistance thermometers and calibrate bath temperature control platinum resistance thermometers), after waiting for 5 minutes, it is enough to ensure the accuracy of the two measurement data. consistency. Then start the recording time for 5 minutes, measure 4 temperature values continuously, calculate 3 "heating rate deviations per minute", and select the maximum value as the "heating rate deviation". The temperature rise rate deviation is expressed as a relative percentage, which is more concise and intuitive.

The temperature calibration bath with the function of adjusting the heating rate can carry out the test of this project.

The test of the heating rate of the calibrate bath is generally selected to be carried out at the upper and lower limits of the actual working temperature range of the calibrate bath. It is also possible to randomly measure the heating rate of other temperature points within the working temperature range of the calibration bath according to user needs. The test of the heating rate of the calibrate bath generally chooses 1°C/min, and other indicators can also be selected according to the needs of users.

Set the temperature of the calibrate bath temperature at the lower limit temperature (or close to the upper limit temperature), insert the fixed thermometer into the 1/2 depth position in the working area through the instrument jack, wait for at least 10 minutes after the calibration bath reaches the set temperature or the stability required by the instruction manual time. Increase the set temperature of the temperature calibration bath by 10°C, and set the heating rate to 1°C/min. After the calibrate bath temperature is heated for 5 minutes, start to record the temperature indication of the platinum resistance thermometer, and then record the temperature indication once every 1 min. 3min, a total of 4 temperature values are measured. Take the maximum value as the temperature rise rate deviation, and the temperature rise rate deviation rh=max(rh(1), rh(2), rh(3), rh(4), rh(5))

| Previous:What is the Fob Price of Temperature Calibration Bath? | next:DEARTO Welcomes the Year of the Horse: Galloping into a New Era of Success |

Headquarter Address :Tai'an High-tech Development Zone, Shandong Province

Headquarter Address :Tai'an High-tech Development Zone, Shandong Province

Telephon :+86 0538-5089056 +86 13953856217

Fax : +86 0538-5059718

After sale:+86 0538-5050959

Website : www.tadt.com.cn

E-mail : tadtzdh@dearto.cn

Copyright© Tai'an Detu Automation Instrument Co., Ltd. Lu ICP 14024757-1